Book a Virtual Facility Tour

Want to try it on for size? Book a virtual facility walkthrough today. Witness the power of 3D modeling and let’s chat about how to bring your next industrial project to life.

.gif)

3D Modeling is your visual roadmap, bringing your project to life before breaking ground. Whether it's swift frontend engineering design, eerily accurate process emulation, or streamlined operations optimization, our 3D modeling and simulation expertise saves you time, money, and the headaches of a project going off course. Projects never go awry, right?

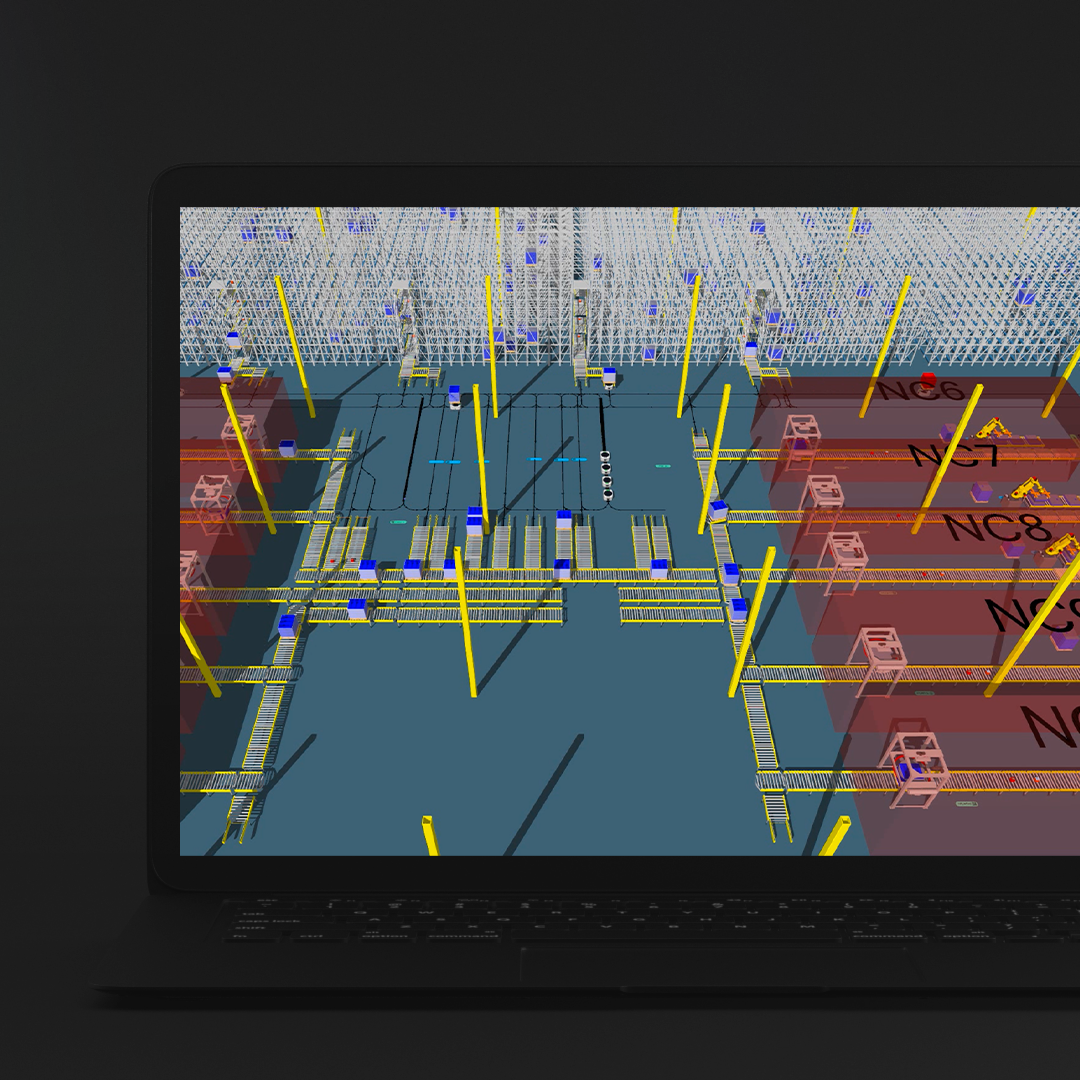

Modeling allowed us to analyze travel paths for the autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) slated for use on the factory floor for a new pet food facility. By identifying potential interferences with people and equipment operations in the early stages, we fine-tuned travel paths, optimizing efficiency. The simulation results were flat-out eye-opening—they not only revealed the possibility of reducing the required number of AGVs/AMRs by half, but also translated into substantial savings, cutting costs by over half a million dollars in equipment and approximately $1 million in electrical, programming, commissioning, and other expenses associated with the AGVs/AMRs.

Someone had a good day delivering that news!

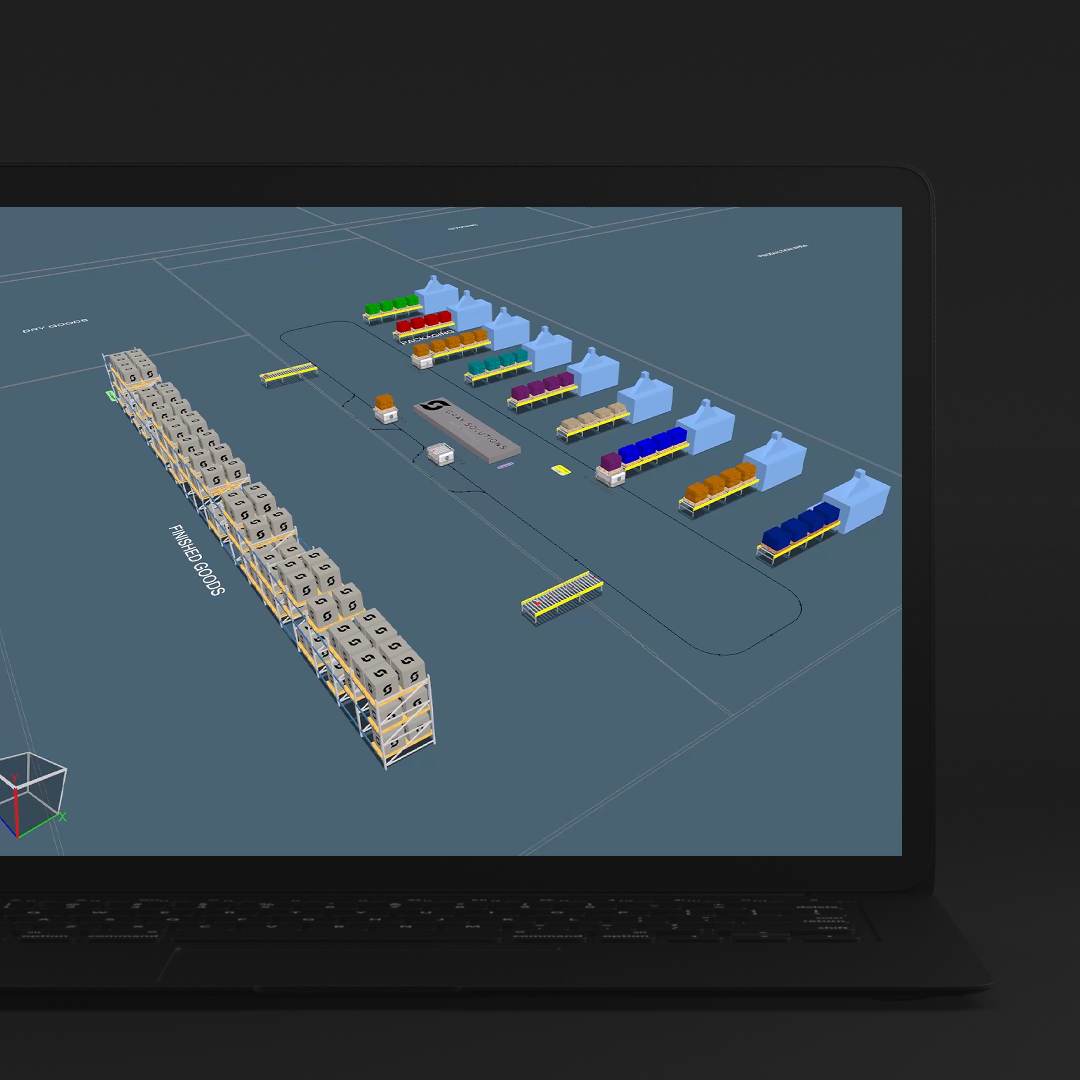

During the front-end design we used 3D modeling to sketch out the game plan for a massive distribution center warehouse to visualize automated delivery to and from the production lines. We used our model to dissect AMRs/AGVs path options, fine-tune product flow throughput, strategically place equipment, and test KPI metrics. 3D modeling allowed us to address potential bottlenecks before they happened and present a clear picture of the project to stakeholders across the business.

No crystal ball, just some savvy simulation.

Caught in the throes of growth, a produce packaging company found their single robotic case packing system playing catch-up and we knew just what to do. Emulate3D and Fanuc Roboguide were key for pre-evaluation, revealing the necessity for dual robots to meet current and future throughput demands. PLC emulation was also utilized for hard-core testing of sequential controls. Spatial constraints tried to cramp our style, but a line rearrangement from input to final packaging output did the trick.

Leveraging simulation and modeling in this project delivered a cost-effective pre-design solution, sparing the customer significant capital in the early phase, and who doesn’t want that?

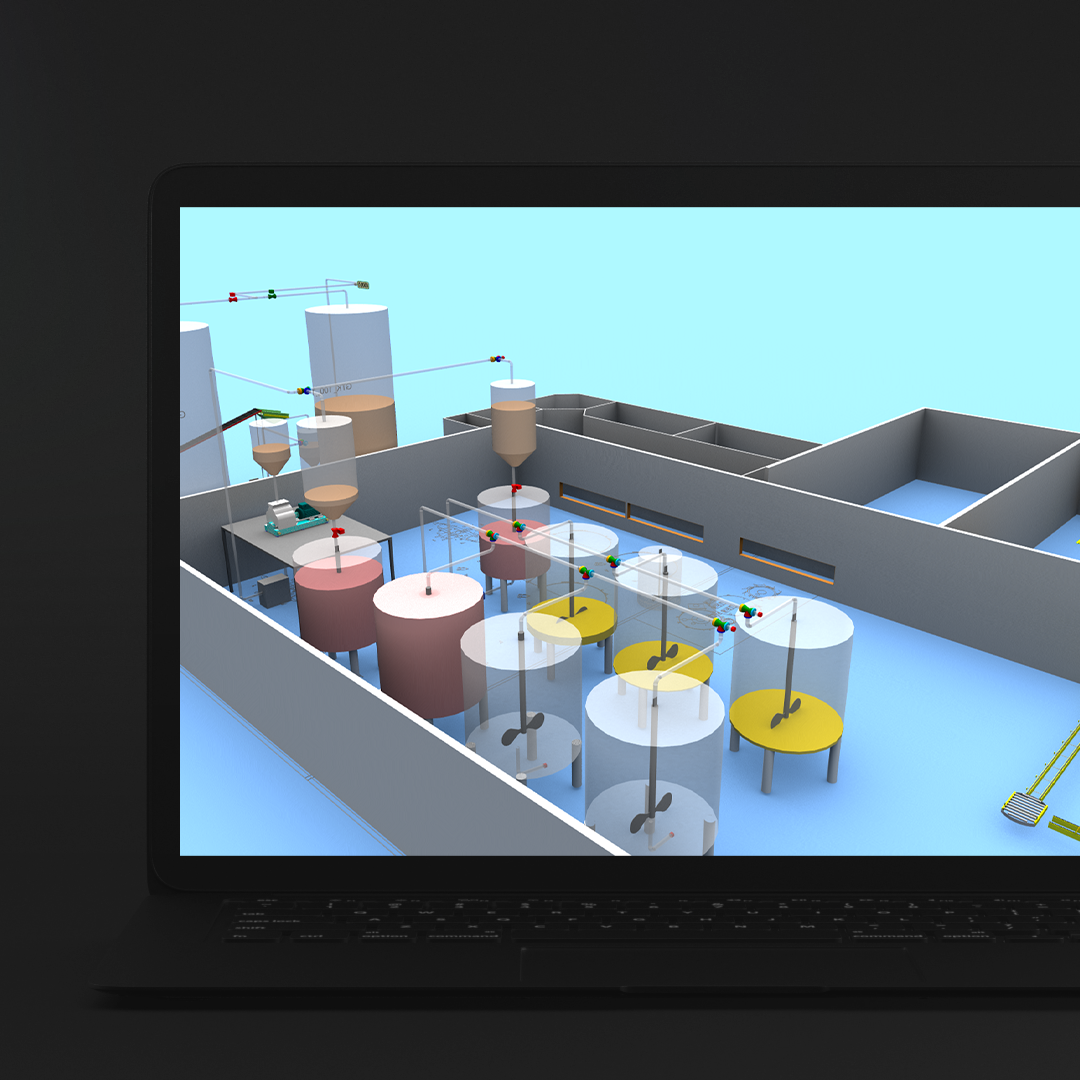

Our expert Solutioneers used 3D modeling for a customer who blends oil products in batches. The model mirrored the existing system, using tanks and pipes process components to fine-tune how liquids flow into each tank before hitting the packaging line. This isn't just a show-and-tell; it's a controls evaluation and early commissioning stress test of fluid transport and tank filling. Next up for this customer is the integration with PLC, HMI, and MES systems, plus a sleek Ansys software upgrade for next-level process analysis.

Don't play the guessing game when optimizing production processes. Skip the time drain and cost headache—embrace a smarter approach.

Want to try it on for size? Book a virtual facility walkthrough today. Witness the power of 3D modeling and let’s chat about how to bring your next industrial project to life.